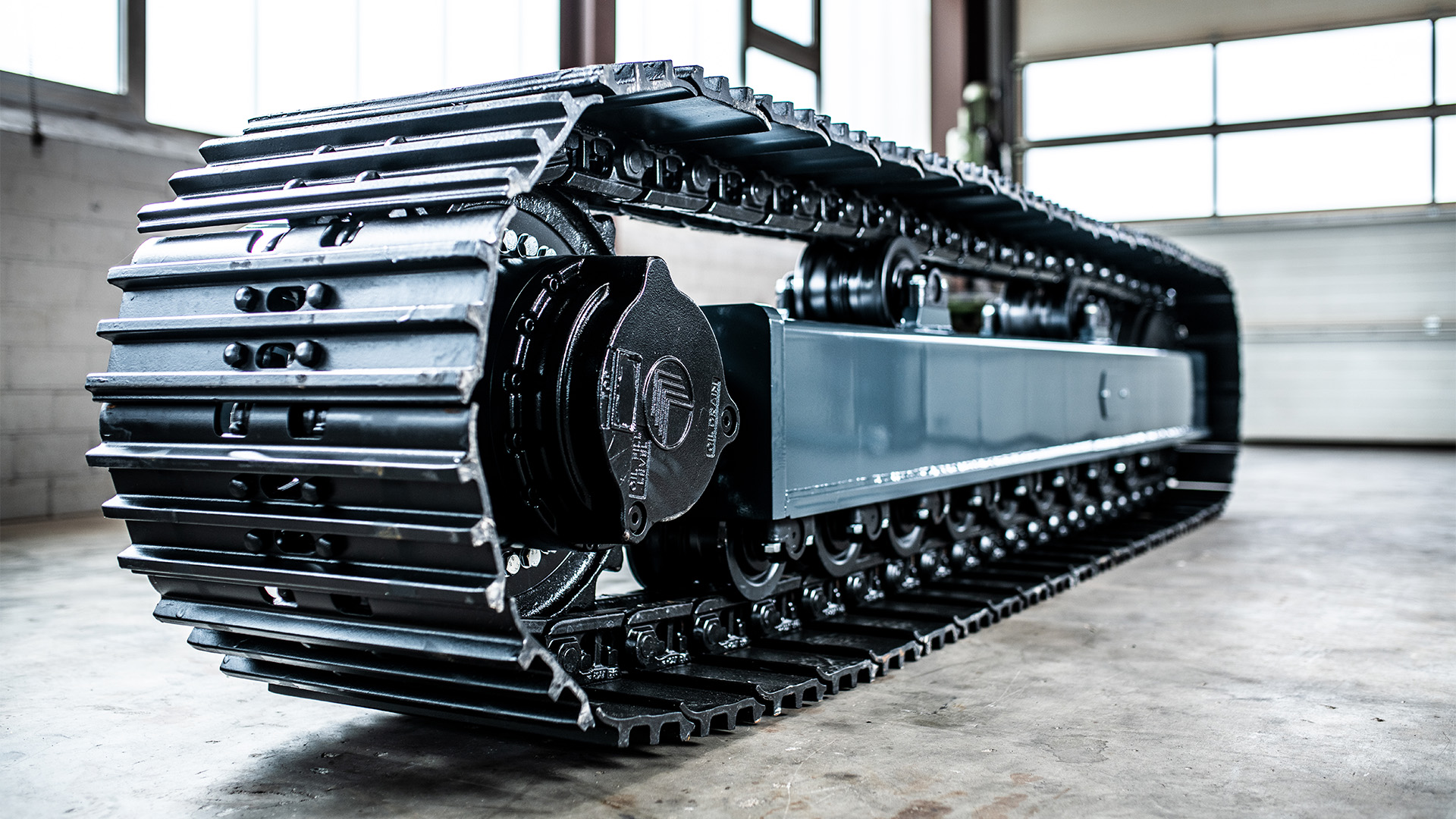

Tracked undercarriages – Solid and indestructible

A tracked undercarriage is the crucial foundation of many mobile machines. It bears the overall weight, ensures stability, and enables reliable movement on uneven or difficult terrain. This naturally includes the tracked running gear as the central element of the undercarriage. Depending on the application, various designs are used – from robust steel tracks to soil-friendly rubber tracks.

Our custom-made crawler undercarriages are used in a wide variety of machines, such as road construction equipment, crawler drilling rigs, milling machines, conveyor systems, underground mining equipment, and tracked mobile crushing plants. This results in solutions that are precisely tailored to the specific application – from traditional construction to specialized industrial plants.

Tracked undercarriages with steel tracks

Steel tracks are considered particularly durable and are primarily used in heavy construction machinery such as bulldozers or large crawler excavators. Within a crawler undercarriage, they consist of individual links connected by bolts, which reliably transfer the machine’s weight into the ground. Due to their high traction and durability, steel tracks are ideally suited for challenging soils, stony terrain, or extreme loads. The higher ground pressure is a deliberate compromise in favor of maximum stability.

Tracked undercarriages with rubber tracks

Rubber tracks are primarily used in more compact machines such as mini excavators, compact loaders, or agricultural equipment. As part of a crawler undercarriage, they offer significantly better ground protection, cause less vibration and leave no damage on paved surfaces such as asphalt or cobblestones. Rubber tracks run more quietly and provide greater comfort and flexibility – both for the operator and for the application.

Custom crawler undercarriages – tailored to your specific application

Crawler undercarriages must be adapted to the respective machine weights and the respective intended use in order to meet the different requirements. Lighter machines typically use smaller rubber tracks, while heavy construction vehicles and crawler excavators are equipped with massive steel tracks. Choosing the right weight class depends on various factors, including soil conditions, intended use and required load capacity.

We develop crawler undercarriages individually according to your technical requirements – from the track width to the base plates, rollers, clamping systems and drive assemblies. This results in an undercarriage that fits your machine and your daily use perfectly.

Inquire now

Ready to make your project a reality with a custom-made track? Complete our inquiry form and provide us with specific details about your requirements. Our team will contact you as soon as possible. We look forward to bringing your vision to life and providing you with the best possible solution!